ADVANCED Parts Manufacturing

MSK Precision Products, a PrecisionX Group company, specializes in precision parts manufacturing and assembly for the medical, aerospace & defense, and telecommunication industries.

Join Us at Space Tech Expo 2025 – Visit Booth 408!

June 3-4, 2025, Long beach Convention Center, Long Beach, CA

Core Capabilities

Swiss Machining

We specialize in Swiss machining, crafting small, high-precision components with superior accuracy and surface finishes, ideal for complex parts used in medical, aerospace, and electronics applications.

CNC Machining

Our CNC machining services offer the flexibility to create complex, precise components across various materials, ensuring exceptional accuracy for industries such as aerospace, defense, and medical.

Wire EDM

We provide high-precision wire solutions for critical applications in medical devices, electronics, and telecommunications, ensuring durability, reliability, and top-tier performance.

Secondary Capabilities

Laser Welding

We specialize in Swiss machining, crafting small, high-precision components with superior accuracy and surface finishes, ideal for complex parts used in medical, aerospace, and electronics applications.

Laser Marking

Our CNC machining services offer the flexibility to create complex, precise components across various materials, ensuring exceptional accuracy for industries such as aerospace, defense, and medical.

PrecisionX Full Capabilities

The PrecisionX Group provides deep drawing, progressive stamping, CNC and Swiss machining, laser marking, and laser welding. With broad capabilities and industry expertise, we deliver solutions for complex manufacturing needs. Our brands include GEM, Coining, National Manufacturing, Ditron, and MSK Precision Products.

Industries & Applications Served

Aerospace & Defense

In aerospace and defense, materials that perform reliably in harsh environments are essential. We specialize in high-performance metals like Inconel, Titanium, and Hastelloy, engineered to withstand extreme conditions. Our expertise ensures your parts meet strict industry standards for mission-critical success in even the toughest environments.

Medical Device

Precision is the foundation of success in the medical device industry. We manufacture your high-reliability components to meet stringent regulatory standards, ensuring accuracy, durability, and performance in life-saving devices. Our expertise in deep draw technologies and tight tolerances enables us to support the development of innovative medical solutions.

Satellite & Space

We bring unmatched precision and innovation to the satellite and space industry, producing critical components that must perform in the most extreme environments. Our advanced progressive stamping and deep drawing capabilities allow us to craft complex, high-strength metal parts with the tight tolerances required for space applications.

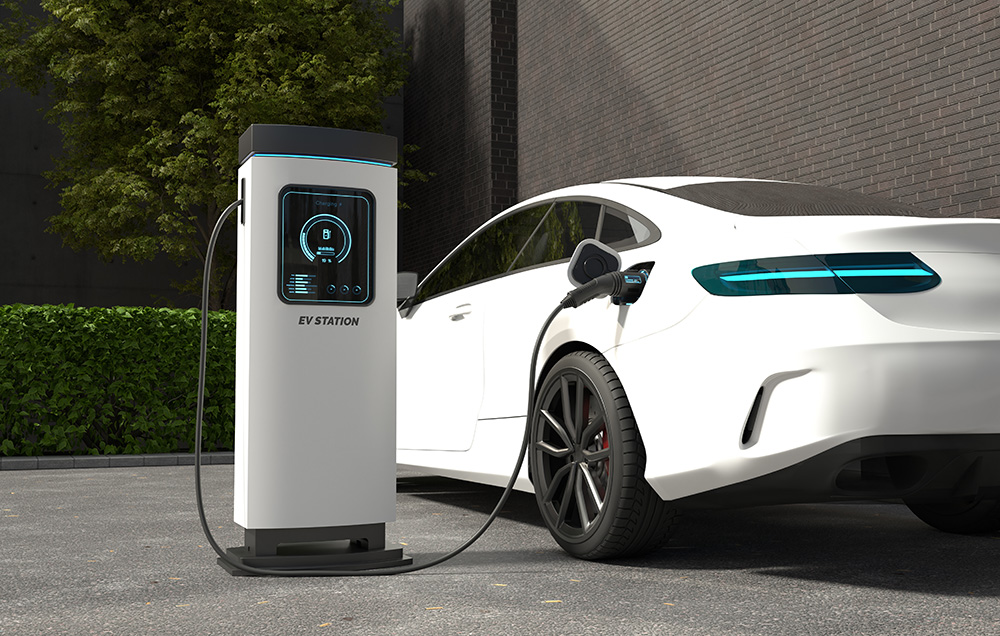

Electric Vehicle

As the need for innovation accelerates, we partner with our customers’ engineering teams to manufacture the critical components that power the next generation of EVs. From precision metal parts to advanced manufacturing solutions, we deliver excellence.

Mining

In the mining industry, precision and reliability are essential. Blasting caps and other critical components are crafted to perform in the harshest environments. By partnering with your engineers, we deliver durable, high-quality solutions that ensure efficiency.

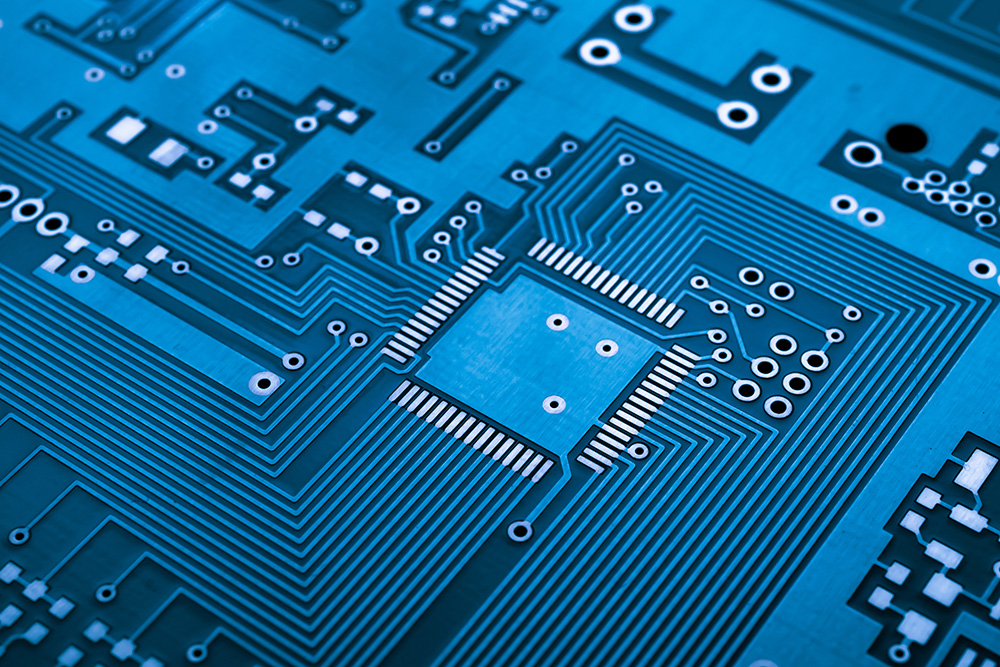

SemiConductor

Our advanced capabilities in metal forming, stamping, and machining ensure the highest quality parts for critical PCB applications. Whether it’s connectors, shields, or custom components, we manufacture to exacting specifications, providing reliable and durable solutions that enhance PCB performance.

Oil & Gas

We specialize in manufacturing critical metal components for the oil and gas industry. From durable housings for subsea equipment to reliable connectors for high-pressure pipelines, and precision-machined components for drilling rigs, our products are engineered to perform in the most demanding environments.

Our expertise lies in working with exotic materials, such as Inconel, Titanium, and Hastelloy, ensuring strength, corrosion resistance, and precision in every part we deliver.

connector

We manufacture precision connectors engineered to perform reliably in harsh environments. Our electrical connectors are designed to withstand extreme conditions, including underwater applications. Utilizing advanced materials and innovative manufacturing processes, we produce connectors that offer exceptional durability and performance in demanding settings such as marine exploration, oil and gas operations, and other challenging industries.

Eyelets / Ferules

We manufacture eyelets and ferrules for a wide range of applications. Our advanced metal forming capabilities allow us to produce high-quality, durable components that meet exacting specifications. Whether used in electrical connections, medical devices, or industrial applications, our eyelets and ferrules are engineered for strength, reliability, and seamless integration. With our expertise in working with various metals, including stainless steel, copper, and brass, we ensure consistent quality and performance in every part we manufacture.

About Us

MSK Precision Products, Inc., a PrecisionX Group company, specializes in high-precision parts manufacturing and assembly for the medical, telecommunication, and aerospace industries.

Located in Tamarac, Florida, MSK offers a comprehensive suite of services, including:

- Precision Swiss-Style Turning

- CNC 5+ Axis Precision Cutter Grinding

- CNC Milling and Turning

- Laser Marking and Welding

- Wire EDM

- Passivation

These capabilities enable MSK to deliver both individual components and complete assemblies, tailored to the stringent requirements of its clients.

MSK upholds the highest quality standards, holding certifications in: ISO 9001, ISO 13485, AS9100D and ITAR Registration.

These certifications underscore MSK’s commitment to excellence in its processes and products.

As part of the PrecisionX Group, MSK collaborates within a network of premier metal component manufacturers, including GEM, Coining, National Manufacturing, and Ditron.

This strategic alignment enhances MSK’s ability to deliver innovative solutions for critical-use applications across various growth-oriented markets.

Certifications include ISO 9001:2015, ISO 13485:2016, AS9100, and ITAR Registered.

As a customer of PrecisionX, you are partnering with a team driven to:

- Uphold an uncompromising commitment to Quality

- Create the best possible Customer Experience

- Maintain Technical Leadership across highly complex parts

- Accelerate Speed to Market from quote to delivery

For more information about PrecisionX Group, please visit our website.